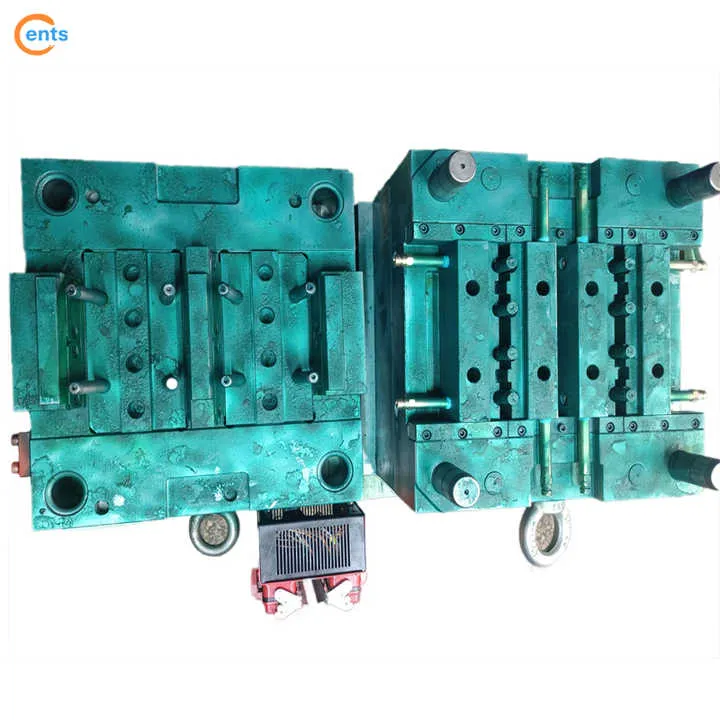

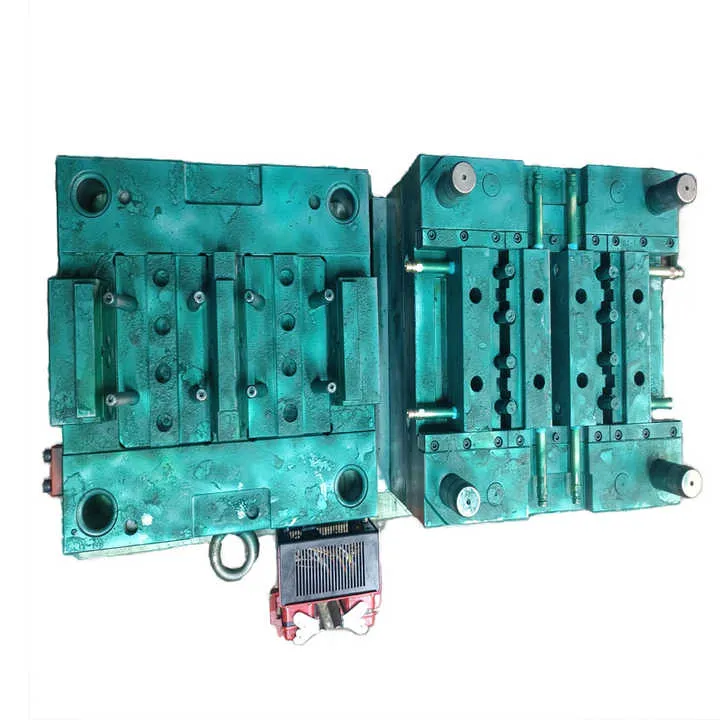

Plastic Moulds Pushing Die Injection Moulding Matrix Cavity for Lipsticks

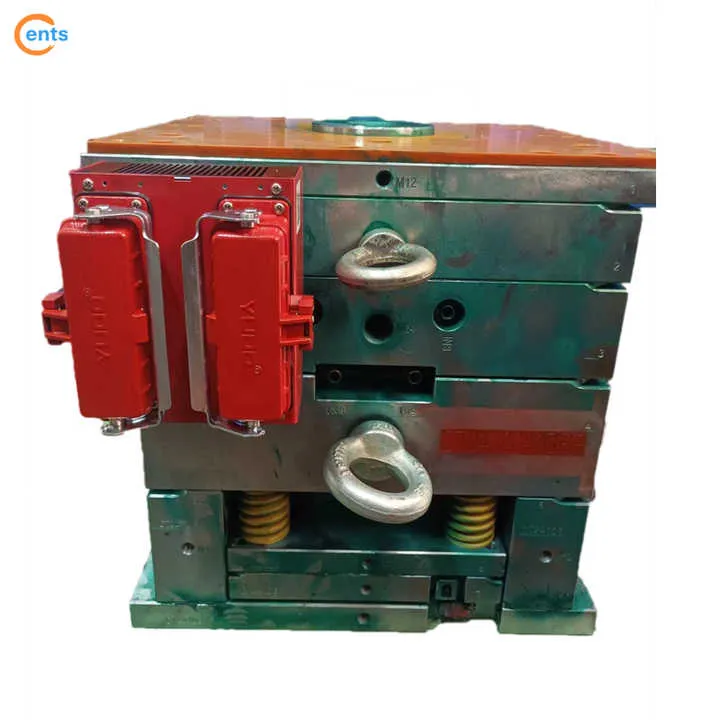

Mould Information

Product Name:Plastic Injection Mould

Mould Standard:LKM/HASCO/FUTABA/DME according to buyer’s requirement

Mold Type:Injection Mould

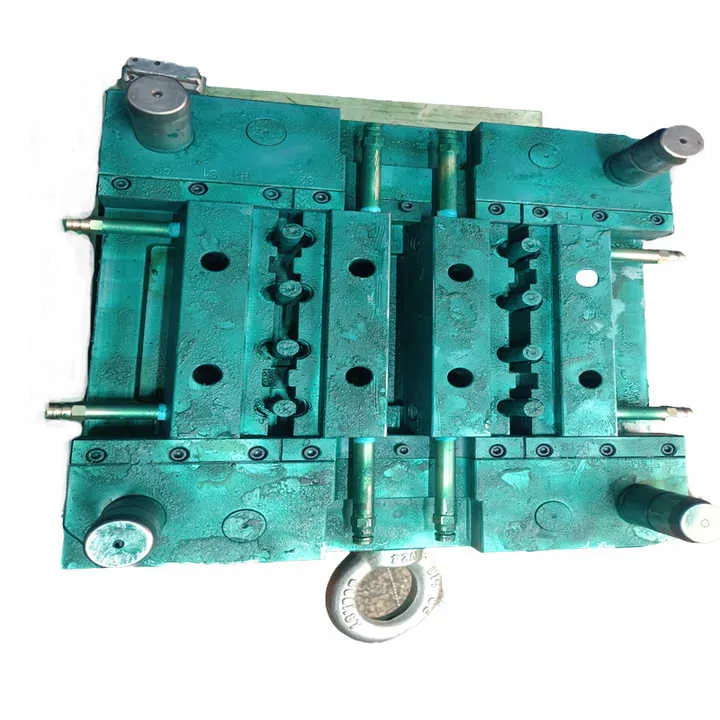

Sprue Gate:Pin-Point Gate, Submarince Gate…

Mold Cavity:Single or multi cavity

Runner Form:Cold Runner or hot runner according to product type and cavity

Mould Material:NAK80, S136, 2344,2316, 718, P20…

Mould life:300000-800000shots

Mould Maintenace:Keep it well maintened

Plastic Part

Material:ABS, PP, PC, ABS+PC, PA66, PTFE, PEI… according to buyer’s requirement

Injection machine:30ton, 100ton, 160ton, 450ton, 500 ton, 800ton…

File Support:3D drawing in Step, UG…

Injection time:According to cavity, product constructure

Injection system:Automatic ejection, Robert Jig system..

Our Advantages

Uncompromised Quality

Strict manufacturing processes and ISO certifications ensure premium molds and plastic products tailored to your needs.

Cost-Effective Manufacturing

Streamlined production and large-scale capabilities deliver high-quality solutions at competitive prices.

Fast Turnaround Times

Equipped with over 60 injection molding machines ranging from 60T to 1000T, we guarantee timely delivery for every order.

Custom Solutions

We offer fully customizable services—from material selection to design—to craft the perfect product for your project.

Advanced Manufacturing Technology

State-of-the-art CNC machining, EDM, and precision tooling ensure durable and accurate results for diverse applications.

Sustainable Manufacturing

Eco-friendly materials and energy-saving technologies support green production and sustainable development.

Reviews

There are no reviews yet.